In the realm of orthopedic surgery, a revolution is underway, and it’s being printed in three dimensions. The Hospital for Special Surgery (HSS) stands at the forefront of this innovation, wielding sophisticated 3D printing technology to create custom-made joint replacements for the most complex of cases. This blog post delves into the transformative impact of 3D printed implants on orthopedics, offering a beacon of hope where standard solutions fall short.

Bridging the Gap with Customization

For the majority seeking joint replacement surgery, the array of standard implants suffices. Yet, for those with unique anatomical challenges, the one-size-fits-all approach is inadequate. Enter the extraordinary capabilities of 3D printing. At HSS, the ability to tailor a joint replacement to the individual’s specific needs has altered the landscape of reconstructive surgery. Dr. Mathias Bostrom, associate surgeon-in-chief at HSS, hails this as a game-changer, allowing for the creation of intricate shapes and designs rapidly, a feat unattainable with traditional manufacturing methods.

Restoring Lives, One Layer at a Time

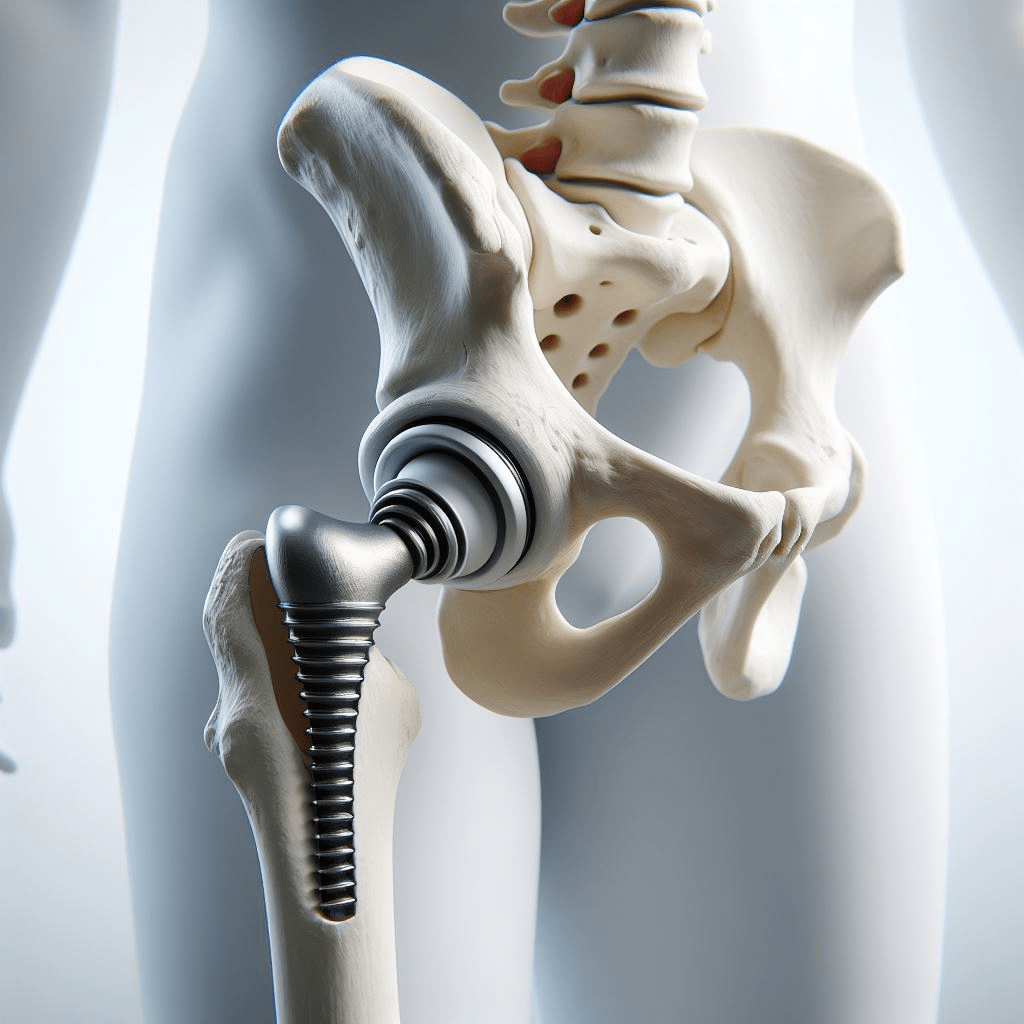

The Complex Joint Reconstruction Center at HSS is where hope is restored. Here, orthopedic surgeons encounter patients grappling with severe deformities, significant bone loss, or the need to redo failed joint replacements. Custom-made 3D-printed implants are not just replacements; they are lifelines that restore function, mobility, and independence. Crafted from titanium, these implants begin as fine metal powder, meticulously layered and fused using a laser or electron beam, culminating in a structure that promises relief and renewed mobility.

From Concept to Reality

The journey from a plastic model to a titanium implant encapsulates over a decade of progress. Initially, 3D printing at HSS was utilized to create precise models of patients’ joints, aiding surgeons in preoperative planning. Dr. Mark Figgie, chief emeritus of the Surgical Arthritis Service at HSS, emphasizes the revolutionary impact of having such models, ensuring the perfect fit and optimal surgical outcomes.

Today, the technology has evolved to directly produce the titanium implants that become part of the patient. These implants are often the final resort for patients requiring complex or revision hip, knee, shoulder, or elbow replacements.

The Final Frontier in Orthopedic Solutions

Patients arriving at the Complex Joint Reconstruction Center often view HSS as their last hope. Dr. Bostrom acknowledges this sentiment, understanding the gravity of their situations. The promise of a custom solution, tailored to their needs, offers a glimmer of hope in their arduous journey.

Navigating the regulatory landscape, each new medical device, including patient-specific 3D-printed implants, must secure FDA approval. Despite the slow process, often expedited through a “compassionate use” waiver, the outcome—a custom implant that fits perfectly and functions optimally—is indisputably worth the wait.

As we look to the future, the promise of 3D printed joint replacements stands as a testament to human ingenuity and the relentless pursuit of medical advancement. At HSS, the future isn’t just printed; it’s personalized, promising a new lease on life for those once thought beyond help.

Reference: Custom 3D-Printed Orthopedic Implants Transform Joint Replacement Surgery